A LOOK BACK AT A LEGACY OF AIR MANUFACTURING INNOVATION.

1993

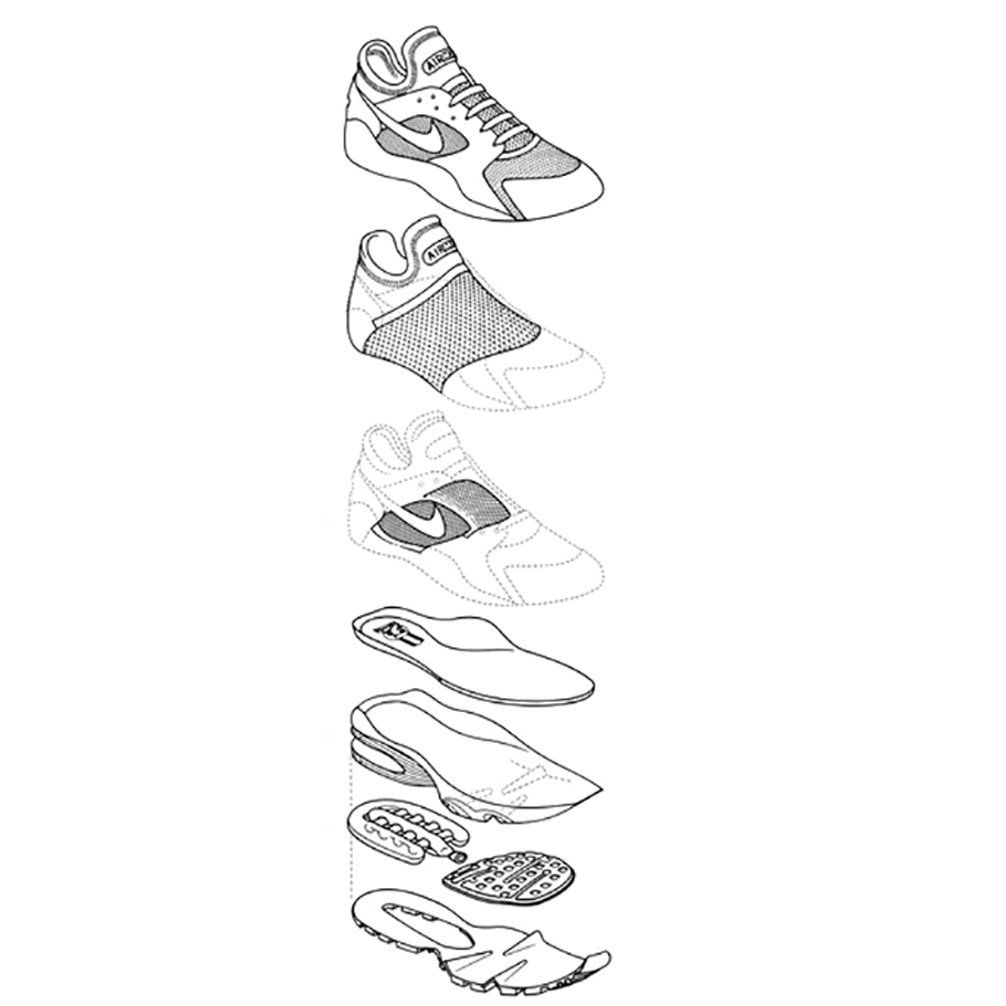

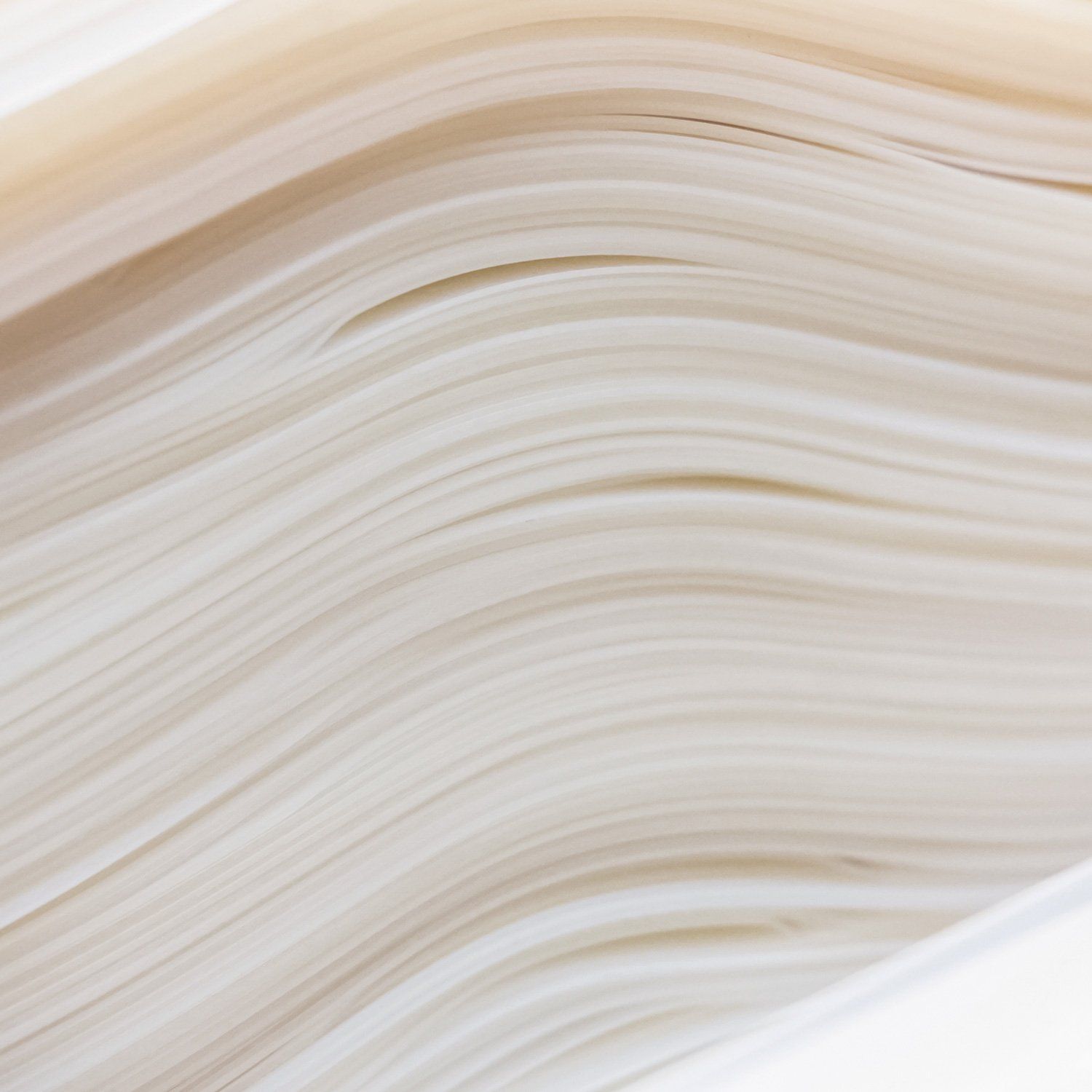

Blow-molding is debuted in the Air Max 93. It is a significant step forward in the pursuit of a foamless shoe, and a testament to the drive of the Tetra team whose plant was shut down by a devastating flood in the same year. Symbolizing the shoe that boasted the first fully-visible air wedge, the Air Max 93 is heralded as the cornerstone of visible Air, setting new standards of cushioning.

1998

Tetra Plastics officially becomes Nike IHM, Inc., a subsidiary of NIKE, Inc.

2016

Nike In-House Manufacturing (IHM) is rebranded Nike Air Manufacturing Innovation (Air MI).

We’re the trailblazers of performance plastics, spanning industries to deliver cutting-edge products.

We fine-tune technology to deliver precision performance in Beaverton, Oregon and St. Charles, Missouri.