WE GO BEYOND AIR TO PRODUCE INDUSTRY LEADING COMPONENTS FOR FORWARD-THINKING GLOBAL PARTNERS.

Our St. Charles, Missouri, facility, NIKE IHM, Inc. – doing business as Air Manufacturing Innovation – works with companies worldwide to design, develop and manufacture custom performance plastic solutions. We leverage next-generation technology, computational design and decades of innovative manufacturing experience to produce game-changing products across diverse industries – automotive to action sports to medical.

Product Capabilities

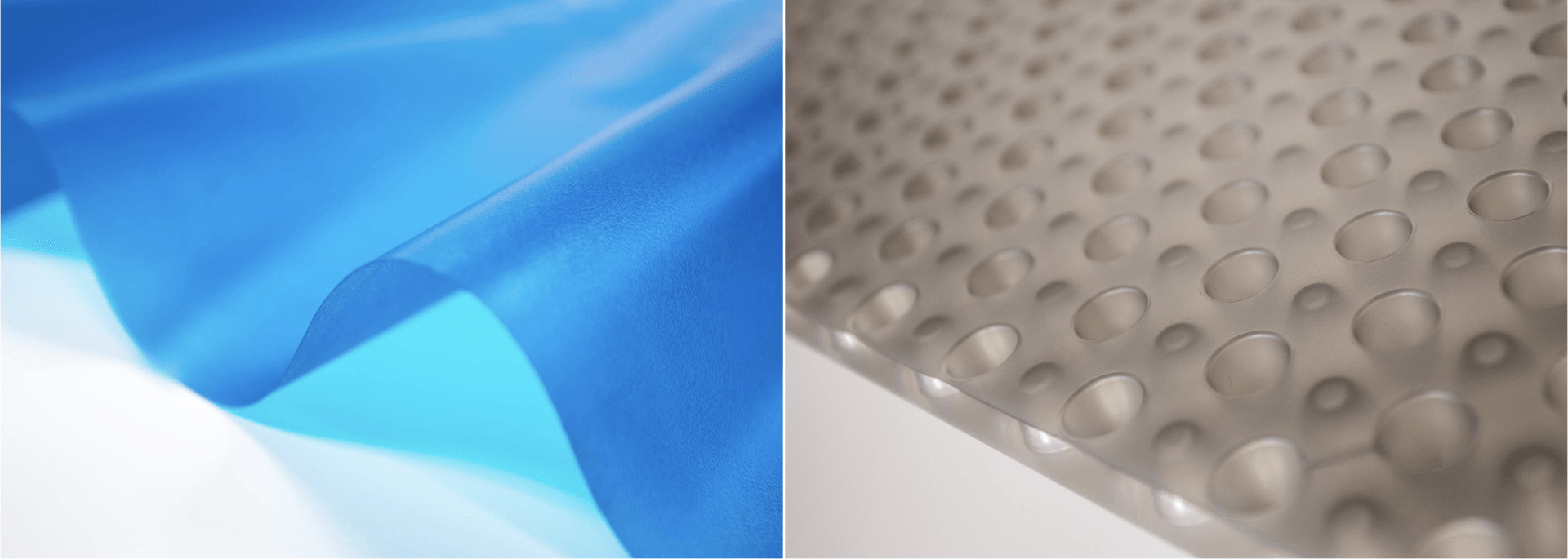

We specialize in custom extrusion of polyurethane film and sheet – both aromatic and aliphatic. Our technology results in high-quality outputs including flat-die custom sheet extrusion and twin-sheet thermoforming. We are ISO 9001 Certified and pursue manufacturing excellence by enforcing the highest-standards across quality, safety and service.

Thermoplastic Polyurethane (TPU)

TPU is a versatile material (plastic elastomer) across hardness, look and feel. It can be softened to a rubber-like flexibility or hardened for rigid uses, such as protective electronic cases. Color and texture can all be tailored through the production process to suit the needs of a wide range of industries and applications. Benefits of TPU include:

• Abrasion-resistant

• High durability

Extrusion

We specialize in extrusion across a wide range of sizes, thicknesses and product specifications. Extrusion is the process of melting plastic and reforming it into sheets or specific forms. It is ideal to create complex forms and top-quality surface finishes. Because it allows for custom forms and thicknesses, it is a preferred method for producing conveyor belts, weather stripping, wire insulation, window frames and plastic films and sheeting. Benefits of Extrusion include:

• Customizable form and thickness

• Durability

• Water resistant

Thermoforming

We use single-sheet and twin-sheet thermoforming technology to manufacture custom products that contain hollow or double-walled 3D parts. Twin-sheet thermoforming is achieved by simultaneously forming two sheets and then bringing these two sheets together and sealing them during the thermoforming process. Benefits of Thermoforming include:

• High structural integrity

• Custom forms (internal cavities, internal reinforcements, molded-in forms and features)

• Custom features (combine different thicknesses or grades of TPU, custom color options)

Our facility is experienced in designing, developing and manufacturing an extensive range of TPU-based products. For more information or to discuss a specific end-use application, contact our sales team at

nikeihm.sales@nike.com or by phone at (800) 325 4978 or (636) 939-5300.

We’re one of Nike’s boldest and oldest embodiments of Sustainable Innovation.

We fine-tune technology to deliver precision performance in Beaverton, Oregon and St. Charles, Missouri.